Ensuring Proper Airflow: Best practices for hospital air balancing planning & coordination

Molly Meyer and Miles Ryan, both Mechanical Engineers at QSEng, published this article in the March/April 2021 issue of Medical Construction Design magazine.

The required sophistication of air systems in a healthcare setting and the process of working in existing hospitals present many obstacles to the testing, adjusting and balancing, or TAB, process. Healthcare is a continuously growing and changing industry and so are the buildings that serve the patients, visitors, clinical staff, administration and support staff. Many healthcare settings are a mix of old and new infrastructure fitting into tight footprints with frequently changing space functions. The challenges and demands of healthcare design and construction in existing facilities are unique.

TAB is a critical healthcare project activity to ensure system performance criteria are met for a variety of systems such as HVAC, plumbing, etc. TAB is the process by which HVAC system and equipment performance is tested, water and airflows are adjusted to meet the system design requirements, and finally systems are balanced to meet the design intent. Optimum and reliable system performance is tied to successful completion of the TAB process. Outlined below are five best TAB practices to ensure successful project outcomes in existing hospitals:

- Perform existing conditions assessment prior to design

While working in existing hospitals, there are bound to be surprises during the construction phase. Performing a thorough existing conditions assessment prior to design can identify potential issues and requirements for scope modifications, which will save the owner money in the long run. Such assessments are commonplace, however, involving the TAB firm and commissioning provider in them is far less so. These key players bring different perspectives to the team, which will help identify issues that may otherwise go unnoticed.

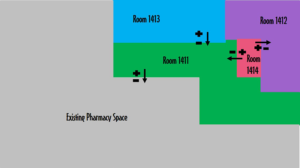

In a recent project to bring a pharmacy into USP 800 compliance, several existing wall assemblies were to be utilized in the renovated area. Those wall assemblies were to support the cascading pressure requirements. Due to crowded ceiling plenums above the renovated spaces, an open plenum return concept was employed by the HVAC designer. For the required pressure relationships to be maintained, the wall assemblies above the hardened ceilings needed to be as tight as the exposed portions below. However, these existing above-ceiling wall assemblies were never investigated during the existing conditions assessment.

During balancing, the TAB firm quickly identified these leaky, above-ceiling wall assemblies were preventing the pressure requirements from being met. The required repairs to those wall assemblies after substantial completion were costly and delayed turnover of the project.

- Detail constraints, compliance requirements in design documentation

TAB contractors and commissioning providers often need to deviate from scheduled design parameters to ensure the systems perform as intended. They need to know how much flexibility they have at their disposal without compromising other requirements of the system. Such constraints need to be clearly documented in the design documentation, otherwise the project runs the risk of these team members unknowingly making adjustments that compromise other aspects of the project or being substantially delayed awaiting direction from the engineer-of-record.

One space in the previously addressed pharmacy project had its supply air variable air volume box modulating airflow to maintain a space pressure setpoint. The space was over pressurized, and the minimum airflow setpoint for the supply air VAV box needed to be lowered below the value scheduled by the design engineer.

Concerned that the lower value required to attain pressure control would pull the space out of compliance for air change rate requirements, the project team had to document the issue, reach out to the engineer-of-record and wait for direction. Time was lost in this process and the turnover of the space was impacted due to the tight project schedule. Documenting the system constraints and compliance requirements in the design documents can allow the iterative process of balancing airflow and controls tuning to be more efficient when all information is available to the field team.

- Customize TAB specification to meet project needs

The TAB specification is far too often a copy and paste item in the design package. A customized TAB specification is always advised, but absolutely vital when dealing with the complex, and often unconventional, TAB processes required when working in existing hospitals. One way to specify a quality TAB process is to integrate third-party certification requirements and adherence to standards, such as the AABC National Standards for Total System Balance.

This best practice was vital on a project which consolidated four existing air handling units into a single air system. A new, consolidated roof top unit tied into the existing horizontal air distribution systems on each floor. Modifications to the existing terminal devices were not in the project scope, thus the TAB firm was instructed to ensure the static pressures available in the main supply trunks on each floor were equal to or greater than pressures the original systems had been providing.

Preconstruction TAB readings were imperative to successfully complete this activity. Without detailing the requirement for preconstruction readings in the TAB specification, the information needed to balance the new RTU would not have been known.

To add to the complexity, the floors were not transitioned over to the new RTU simultaneously. The requirement for continued operations in the hospital necessitated a phased approach. Again, preconstruction TAB readings were imperative. Existing exhaust system airflow measurements proved vital in selecting appropriate setpoints to which the RTU was controlled to ensure building pressure was maintained both during construction and after project completion.

- Hold TAB integration meetings

Having a TAB integration meeting late in a project’s construction phase helps clarify the complex and often unconventional TAB requirements. Key attendees include:

- general contractor

- mechanical contractor

- commissioning provider

- design team

- owner’s representative

- facility manager

- controls contractor

- packaged equipment vendors

- TAB firm

The TAB integration meeting should take place after the temperature controls submittal is approved. That approved controls submittal will list the information (setpoints, alarm thresholds, etc.) required to be determined by the TAB firm. The process the TAB firm will follow to obtain such information can then be discussed at this meeting.

Coordination with packaged equipment vendors also needs to occur at the TAB integration meeting. Packaged kitchen exhaust systems or laboratory hoods often have startup performed without coordination with the TAB firm, yet startup of these systems impacts the air balancing of the overall space they serve. A TAB integration meeting will facilitate the required coordination between these parties.

- Provide consolidated, accurate as-built documentation

Ensure every project concludes with consolidated, accurate as-built documentation. Facilities departments are encouraged to develop and maintain standards for how such information is to be submitted to the facility staff. This will allow facility operations staff to make better use of the documentation when troubleshooting the systems in the future.

In the pharmacy revamp project previously mentioned, the commissioning provider detailed the specific pressure relationship diagram and layout of information to be included in the TAB report so that during the commissioning process the values in the TAB report could be verified and repeated throughout the range of system and space operations. That TAB report also documented all the related setpoints at which the various mechanical systems were operating. That same diagram, with the defined design setpoint nomenclature and values, was used on the building automation system graphic screens for the space. This consistency between BAS graphics and the TAB report has proven useful to the facilities operations staff in troubleshooting post-project performance issues related to maintaining the critical cascading pressure relationships.

Case studies have confirmed the aforementioned best practices increase the probability for successful outcomes of TAB in hospital projects. Best practices include existing conditions assessment prior to design, design documentation detailing project constraints, customized TAB specification to meet the project needs, hold TAB integration meeting(s) and consolidated, accurate as-built documentation.

These best practices start at the beginning of the project. TAB should not be considered a singular activity that occurs at the end of the schedule, but as an integrated part of the entire design and construction process.

Meyer, P.E., and Ryan, P.E., are commissioning engineers at Questions & Solutions Engineering, a member firm of the AABC Commissioning Group.