Improving HVAC Operations – Part II: Controlling Temperature, Managing Humidity

Abstract:

Maintaining a solid understanding of how common HVAC systems are controlled is essential to effectively troubleshooting them. It is also necessary for optimizing the energy performance of such systems. Improving the knowledge base of HVAC control sequences throughout the Department of Defense, for these purposes, was the driving force behind the resurrection of the Air Force Institute of Technology’s course entitled WENG 563 HVAC Control Systems. This 5-part series is written to support that course. These articles seek to explain common HVAC control sequences, where such sequences are effective, and the performance implications that arise when they are applied inappropriately.

Please enjoy Part II of this series below written by Questions & Solutions Engineering’s own Miles Ryan, PE, CEM.

Part II: Controlling Temperature, Managing Humidity

A recent report from the Pacific Northwest National Laboratory estimates that the total commercial building energy consumption in the United States could be reduced by 29% through improved control our of existing heating, ventilation and air conditioning (HVAC) systems (Fernandez et al, 2017). The Air Force is actively seeking to capitalize on such opportunities (Ryan, 2017; Ryan & Dill, 2019). However, at times we can overdue it. If we become so aggressive in our efforts to save energy that we create an unacceptable work environment, then we have lost focus on why we have HVAC systems to begin with. A common example of this presents with excessively high humidity levels in spaces served by a multi-zone, single-duct variable air volume (VAV) system.

The VAV System

Chances are you are sitting in a space served by such a VAV system, as they have become the norm for commercial buildings. As the cooling requirements for an occupied space fluctuate throughout the day and year, the system varies the amount of cool air that is sent into the conditioned space. Since the power consumed by the system’s fans increases exponentially with increases in the amount of airflow being pushed, VAV systems can offer substantial energy savings by reducing airflow during periods of low cooling requirements.

Supply Air Temperature Reset

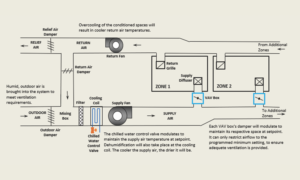

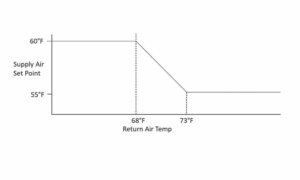

An additional avenue for these systems to save energy is through a supply air temperature setpoint reset control sequence. The VAV box serving each space contains a damper which modulates the airflow to the space, while the air handling unit (AHU) works to ensure a relatively constant temperature supply air is available (see Figure 1). If cooling requirements for the spaces being served decrease, the amount of airflow sent to those respective spaces will reduce as well. However, when occupied, a minimum amount of airflow must be maintained to those spaces for ventilation purposes. This will also help prevent the supply fan from operating in an inefficient (and potentially unstable) region on its fan curve. Maintaining minimum airflow can at times result in too much cool air being supplied to the space, and the space temperature will drop below setpoint. The system would then be overcooling the space, which can create comfort concerns and typically indicates energy waste. If enough of the spaces served by the system are overcooled, this would be realized by a drop in temperature in the common return ductwork. Therefore, a simple, yet common control sequence is to reset the supply air temperature setpoint when overcooling is obviously occurring (see Figure 2).

Figure 1: Operation of a multi-zone, single-duct VAV system during the hot, humid day scenario described in this article. Note: Adding a reheat coil to the VAV box could eliminate the overcooling of spaces. However, often such reheat capability is forbidden on Air Force installations during summer months in order to save energy. If reheat is allowed, supply air temperature reset is even more essential to minimize energy waste associated with reheat. Since a reheat coil would not remove moisture, the system’s susceptibility to excess humidity in the spaces remains even when reheat is used.

Figure 2: Example of a simple supply air temperature setpoint reset schedule. More advanced logics exist (ASHRAE, 2018), however the humidity concerns highlighted in this article can occur regardless when humidity is not measured and directly controlled for.

Implementing such a supply air temperature setpoint reset can mitigate the overcooling of spaces and can thus save energy. However, in humid climates, being too aggressive with this schedule can be detrimental. These VAV systems are most often controlled to maintain the conditioned spaces at their respective temperature setpoints. Space humidityis rarely controlled for directly in Air Force facilities, but adequate dehumidification occurs back at the cooling coil in the AHU when it produces cooler supply air temperatures.

Case Study

Excessive humidity in the occupied space can be realized when we allow our supply air temperature setpoint to rise too high. For example, AHU-1 at Building 643 on the Air Force Institute of Technology’s (AFIT) campus serves 4 classrooms, a storage closet and a conference room and has previously created such a scenario. Let’s explain.

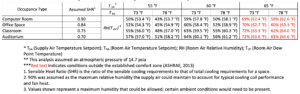

Imagine the air leaving the mixing box is very hot and humid (e.g. dew point temperature above 62°F), and substantial dehumidification is being performed by the cooling coil. If the supply air was initially 55°F and 90% relative humidity, a fully occupied classroom’s relatively humidity would balance out comfortably at around 55% for a space temperature of 73°F. Let’s assume the other 3 classrooms then became unoccupied and began to be overcooled. The return air temperature would drop and the supply air temperature setpoint reset control sequence would initiate. If the supply air temperature rose to 60°F and was still at 90% relative humidity leaving the AHU, more airflow would be required by the classroom which is still occupied. With such supply air conditions, the space’s relatively humidity would still balance out at a reasonable 63% for the same space temperature of 73°F. Raising the supply air temperature further to 65°F with again 90% relative humidity would result in even higher airflow requirements (potentially more than the system could provide the space), and the relative humidity of the space could balance out at an unacceptable 72%.

Periods of such excessive space humidity were occurring in classrooms of Building 643 during humid days. Thus, the 88th Civil Engineer Squadron’s Industrial Controls Shop reduced the maximum supply air temperature setpoint to 60°F. The humidity concerns in occupied spaces then ceased. This initially resulted in overcooling of spaces served by AHU-1 when minimally occupied, but further investigation identified higher-than-design minimum airflow rates for each classroom had been programmed into the control system. Once those minimum setpoints were reduced, only negligible overcooling occurred in unpopulated classrooms. During the process, an inappropriately high minimum speed setting on the supply fan’s variable frequency drive was also identified and corrected. This case study is a great example on how thoroughly investigating one issue often leads to the discovery of others, and such a process almost always results in increased comfort and decreased energy consumption.

Table 1 shows the previous analysis extrapolated for a variety of occupancies, supply air and room air temperature setpoints. It shows space absolute humidity levels (i.e. dew point temperature) increase with rising supply air temperatures, but also increase when space temperature setpoints are raised. All humidity values in red fall outside of the accepted comfort range (ASHRAE, 2013). This table can serve as a guide for what high limit to implement for a particular supply air temperature setpoint reset control sequence. Beware that values in this table are worst case scenarios in hot, humid climates. A high limit for the supply air temperature setpoint no greater than 60°F is suggested to be used for humid climates, and 65°F for hot, dry climates (ASHRAE, 2018).

Conclusion

Optimizing our HVAC systems to reduce energy consumption is absolutely vital. However, there is no sense in running our HVAC systems in a manner that creates unacceptable work conditions. In such instances, it would be better to not run the systems at all.

References:

- ASHRAE/ANSI Standard 55. (2013). Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating and Air Conditioning Engineers.

- ASHRAE Guideline 36. (2018). High Performance Sequences of Operation for HVAC Systems. American Society of Heating, Refrigerating and Air Conditioning Engineers.

- Fernandez, N., Katipamula, S., Wang, W., Xie, Y., Zhao, M., & Corbin, C. (2017). Impacts of Commercial Building Controls on Energy Savings and Peak Load Reduction (USA, Department of Energy, Pacific Northwest National Laboratory).

- Ryan, M. (2017). HVAC Controls: Untapped Potential in the Fight to Save Energy. Air Force Civil Engineer Magazine. 25 (1).

- Ryan, M., Dill, J. (2019). Developing Field Competence: The U.S. Air Force’s Approach to HVAC Education. ASHRAE Journal, 61 (5).

Ryan is a commissioning engineer at Questions & Solutions Engineering in Chaska, MN. As an Air Force Reservist, he serves as a mechanical systems instructor at the Air Force Institute of Technology (AFIT). He is one of the developers of the HVAC Control Systems course taught at AFIT.