Improving HVAC Operations – Part III: Accurately Aligning Occupancy Schedules

Abstract:

Maintaining a solid understanding of how common HVAC systems are controlled is essential to effectively troubleshooting them. It is also necessary for optimizing the energy performance of such systems. Improving the knowledge base of HVAC control sequences throughout the Department of Defense, for these purposes, was the driving force behind the resurrection of the Air Force Institute of Technology’s course entitled WENG 563 HVAC Control Systems. This 5-part series is written to support that course. These articles seek to explain common HVAC control sequences, where such sequences are effective, and the performance implications that arise when they are applied inappropriately.

Please enjoy Part III of this series below written by Questions & Solutions Engineering’s own Miles Ryan, PE, CEM and his colleague at the Air Force Institute of Technology Joshua Dill, PE, CEM.

Part III: Accurately Aligning Occupancy Schedules

The term occupancy schedule can have two very similar, yet distinct meanings when discussing facilities. It could mean the time schedule of when people are actually in the building, or in certain portions of the building. It could also mean the time schedule of when the building automation system (BAS) thinks the building, or a portion of it, is occupied. Ideally, the latter would match the former as there is substantial energy savings to be had during periods of unoccupancy. For example, the BAS could turn off heating, ventilation, and air conditioning (HVAC) systems during such periods, or at least operate them in a manner which consumes less energy. For example, if the system can’t completely shut down, there is no sense in spending energy to condition cold, or hot and humid outdoor air for ventilation purposes if no one is present. Energy can also be saved by raising the room temperature setpoints in the summer, or lowering them in the winter, when no one is present to keep comfortable.

Occupancy Schedule Alignment

Correctly aligning occupancy schedules might be one of the easiest no-cost modifications we can make to our HVAC systems to save energy. However, a 2014 report from the Air Force Audit Agency found 225 of 453 facilities visited failed to do so (Air Force Audit Agency, 2014). This should not be too difficult for the many buildings with set work hours that are very rarely deviated from. Even if someone unexpectedly decides to work late, or on a weekend, there are numerous control overrides that could be programmed into the BAS to allow for the systems to run temporarily, albeit not at full-throttle.

Fluctuating Occupancy

Some unique spaces have occupancies that can be difficult to predict, however. One example is Air Force Institute of Technology’s (AFIT) central auditorium, Kenney Hall. Kenney Hall can seat 750 people, which means high ventilation requirements and corresponding high energy costs. Failure of the ventilation system to engage correctly when the space is occupied can create air quality concerns. Failure to disengage correctly when unoccupied can be devastating for energy conservation efforts. The auditorium is only occupied about 15% of the normal working hours in a typical year. Therefore, it would make no sense to match the space’s occupancy schedule programmed into the BAS to that of the occupancy schedule used for surrounding administrative areas. However, that is what has been done in the past, resulting in the conditioning of large quantities of outdoor air when the space was actually unoccupied. Additionally, the auditorium is rarely fully occupied. So even if the BAS’s occupancy schedule was correct, the system would often be conditioning more outdoor air than need be when engaged.

A common remedy to ensure only the required amount of ventilation is brought into the system is called demand-controlled ventilation (DCV). CO2 concentration is often used as an indicator of occupancy, and rising concentrations is indicative of more occupants in the space. The amount of ventilation airflow being brought can be proportionally increased based on the CO2 concentration realized in the space (Taylor, 2006; ASHRAE, 2018). In theory, such a control sequence should solve the Kenney Hall dilemma. However, CO2 sensors are notorious for falling out of calibration (Fisk et al, 2010). It is for this reason, Unified Facility Criteria (UFC) 3-410-01 prohibits their use for Air Force facilities (Dept. of Defense, 2017). Instead, the document encourages for spaces of intermittent occupancy to implement DCV by use of occupancy sensors.

Using DCV with occupancy sensors can work great in spaces with low occupancy, like offices. In Kenney Hall however, if only one person is present and they trigger the occupancy sensor, then approximately 4,500 cubic feet per minute of excess outdoor air will be provided to the space. Energy waste from excess central plant and fan operation would be significant.

Case Study: Kenney Hall Auditorium

During 2017, a renovation of Kenney Hall’s HVAC system was being designed. To ensure UFC compliance, the use of DCV with multiple occupancy sensors was considered. Depending on how many sensors were triggered, the amount of outdoor air being brought in could be adjusted. As there was no precedent for such a control sequence in an auditorium, and the fact that it would not perform well when occupants sat scattered throughout the space, the designer was understandably hesitant to pursue this. Optical people counting technologies are available, but have been proven unreliable for the nature in which auditoriums are filled and emptied (Fisk, 2010). Occupancy density estimates from real time imagery have shown success (Grabon et al, 2015), but for the Air Force to acquire and learn to operate such technology for a single project would not be feasible. A better solution was clearly warranted.

Photo 1: Kenney Hall is rarely occupied, and almost never fully occupied. Reducing the amount of ventilation air provided to the space during partial occupancy can save substantial amounts of energy.

Members of the Air Force Civil Engineer Center (AFCEC) and AFIT collaborated to devise a control sequence that could meet the intent of the CO2 prohibition, while still capturing the savings potential of DCV. DCV would be achieved by use of the CO2 sensor via the sequence described above.

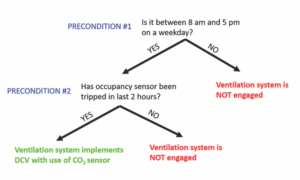

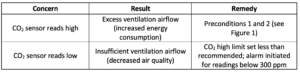

To alleviate AFCEC’s first concern of higher-than-true CO2 sensor readings prematurely engaging the ventilation system, such a sequence would only be allowed to initiate if two preconditions were met. First, the sequence could only operate during normal duty hours, unless an override was given in the event of scheduled evening or weekend use of the space (such non-traditional use would need to be coordinated with the 88th Civil Engineer Squadron’s Industrial Controls Shop, as was currently the case). Second, at least one occupancy sensor (which is best used to detect gross motor movements realized during entrance and exit of occupants) located in the space had detected movement within the last 2 hours. This would prevent the ventilation system from operating for large periods of time with no one present, as could occur if the CO2 sensor fell out of calibration and was reporting higher-than-true CO2 concentration readings.

AFCEC’s second concern was that a CO2 sensor that reported lower-than-true concentrations could result in insufficient ventilation rates during occupancy. To alleviate this concern, a high limit (which would drive the outdoor airflow rate to design levels) was set to 1,650 part per million (ppm), below the recommended high limit of 1,872 ppm for auditoriums (Lawrence, 2008). Additionally, in accordance with ASHRAE Guideline 36, an alarm would be sent to the 88th CES’s Industrial Controls Shop anytime the senor reported CO2 concentrations below 300 parts per million (ASHRAE, 2018). For this control sequence to be implemented, an exemption needed to be approved for the use of CO2 sensors.

Figure 1: Control logic decision tree for ventilation control in Kenney Auditorium

Table 1: Addressing concerns of uncalibrated CO2 sensors.

Conclusion

The exemption request submitted to AFCEC included savings estimates of over $3,100 per year in energy costs associated with conditioning ventilation air due to the implementation of occupancy sensors alone. This conservative estimate neglected additional fan energy and central plant savings that will result at part load conditions due to the use of CO2 sensors. Unfortunately, this exemption request was denied in favor of a human process where AFIT personnel inform the Industrial Controls Shop of projected scheduling so the shop will ensure the ventilation system only runs during occupied periods. This human process was attempted years prior to the renovation and did not sustain personnel turnover. Hopefully more checks were put in place to ensure it works this time around, otherwise energy waste will continue to be widespread.

References:

- Air Force Audit Agency. (2014). Heating, Ventilation, and Air-Conditioning Systems Audit Report. F2014-0008-O2000

- ASHRAE Guideline 36. (2018). High Performance Sequences of Operation for HVAC Systems. American Society of Heating, Refrigerating and Air Conditioning Engineers.

- Dept of Defense. (2017) UFC 3-410-01: Heating, Ventilating, and Air Conditioning Systems.

- Fisk, W. J., (2010). Optical People Counting for Demand Controlled Ventilation: A Pilot Study of Counter Performance (Department of Energy, Lawrence Berkeley National Laboratory). Contract No. DE-AC02-05CH11231

- Fisk, W. J., Faulkner, D. P., & Eliseeva, E. (2010). CO2 Monitoring for Demand Controlled Ventilation in Commercial Buildings(Department of Energy, Lawrence Berkeley National Laboratory). Contract No. DE-AC02-05CH11231

- Grabon, M., Anderson, J., Bushnell, P., Calvo, A., Chadwick, W. (2015). The Sistine Chapel: New HVAC System for Cultural Preservation. ASHRAE Journal, 57 (6).

- Lawrence, T. M. (2008). Selecting CO2 Criteria for Outdoor Air Monitoring. ASHRAE Journal, 50 (12).

- Taylor, S. T. (2006). CO2-Based DCV Using 62.1-2004. ASHRAE Journal, 48 (5).

Ryan is a commissioning engineer at Questions & Solutions Engineering in Chaska, MN. As an Air Force Reservist, he serves as a mechanical systems instructor at the Air Force Institute of Technology (AFIT). Dill is the Deputy Base Civil Engineer at Portland Air National Guard Base. They are the developers of the HVAC Control Systems course taught at AFIT.