Improving HVAC Operations – Part I: Managing Swing Season Cooling Requirements

Abstract:

Maintaining a solid understanding of how common HVAC systems are controlled is essential to effectively troubleshooting them. It is also necessary for optimizing the energy performance of such systems. Improving the knowledge base of HVAC control sequences throughout the Department of Defense, for these purposes, was the driving force behind the resurrection of the Air Force Institute of Technology’s course entitled WENG 563 HVAC Control Systems. This 5-part series is written to support that course. These articles seek to explain common HVAC control sequences, where such sequences are effective, and the performance implications that arise when they are applied inappropriately.

Please enjoy Part I of this series below written by Questions & Solutions Engineering’s own Miles Ryan, PE, CEM and his colleague at the Air Force Institute of Technology Joshua Dill, PE, CEM.

Part I: Managing Swing Season Cooling Requirements

How can it be 85°F in my office, if it is only 72°F outside? You may have asked yourself this question before, and odds are it was during the fall or springtime. These swing seasons can be hard on the HVAC shop. The number of comfort complaints can be excessive, and increasingly unpredictable weather patterns only strengthen that onslaught. In many instances, the shop’s hands are tied. In cooler climates, some facilities require the draining of their chilled water system as a freeze prevention measure from mid-fall through mid-spring. Additionally, local policies may restrict the use of chillers in the name of energy conservation. As a result, complaints of inadequate cooling become commonplace. But there are ways, often overlooked, in which we can help ourselves minimize these comfort complaints as well as deliver on the promise of energy savings.

Minimizing Occupant Discomfort

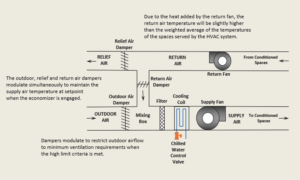

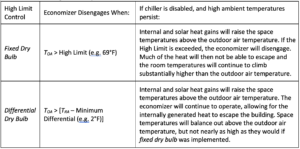

As the theory goes, if cooling is required during periods in which the building’s chiller is disabled – either by necessity or policy – the HVAC system would implement an air-side economizer. This control sequence brings in larger quantities of presumably cooler outdoor air to cool the building. This is often referred to as free cooling, as it can at times adequately cool the building without the use of the chiller, chilled water pumps, and, if present, condenser water pumps and cooling tower fans. However, the most commonly implemented economizer sequence will limit the quantity of outdoor airflow to meet only the minimum ventilation requirements when the outdoor air temperature rises above a fixed high limit (e.g. 69°F). This is to minimize instances of bringing in excess outdoor air when it is warmer than the return air or it has a higher energy content than the return air due to elevated humidity levels. See Figure 1 for an illustration.

This method of high limit control is referred to as fixed dry bulb. It is the most common high limit control, and due to its simplicity and performance, it is often recommended (Taylor & Cheng, 2010). However, for facilities which have their chillers disabled for portions of the year, a differential dry bulb high limit control may more effectively minimize excessive overheating in the occupied space. In this control logic, the air-side economizer will disengage when outdoor air temperatures exceed that of the return air temperature minus some minimum differential. For example, if there was a minimum differential of 2°F and the return air temperature was 75°F, the air-side economizer would restrict outdoor airflow to meet only the minimum ventilation requirements anytime the outdoor air exceeded 73°F. This sequence requires an additional temperature sensor in the return ductwork, but many systems already have this component.

Figure 1: A schematic of a typical air handling unit capable of implementing an air-side economizer.

One example of how differential dry bulb could have alleviated an overheating situation occurred in Building 646 on Air Force Institute of Technology’s (AFIT) campus in late October 2015. The chilled water system for the building had been drained a few weeks prior, and the outdoor air temperature was an uncharacteristically high 80°F. Several spaces in the building experienced temperatures exceeding 94°F. The building’s air-side economizer was following a fixed dry bulb control logic with a high limit of 65°F. Since 80°F outdoor air exceeded the high limit of 65°F, the HVAC system was bringing in only enough outdoor air to meet minimum ventilation requirements. If a differential dry bulbhigh limit control had been implemented, the temperature of the return air would have measured somewhere in the low-90s, which far exceeded the outdoor air temperature. As a result, the outdoor air and relief air dampers would have fully opened, and the return air damper would have fully closed. The building temperature would have balanced out somewhere above 80°F, but definitely below the 94°F previously experienced. When the chiller is no longer available, implementing differential dry bulb high limit control will not always keep the occupied space at the approved indoor temperature setpoints (Air Force Civil Engineer Center, 2015), but it can reduce how far it exceeds them.

Note: TOA is outdoor air temperature. TRA is return air temperature.

Photo 1: AFIT’s Chancellor in front of Building 646. In October of 2015 the building registered temperatures exceeding 94°Fduring the overheating scenario described in this article. “We all understand the importance of conserving energy and reducing the associated costs. But when the temperature in our classrooms exceeded 94°F, it became seriously mission impacting. You just can’t teach or learn effectively under those conditions. We had to find a swing season strategy that would at least mitigate the adverse impacts on the ability of AFIT to accomplish its education mission.” – AFIT’s Chancellor Dr. Todd Stewart, Maj Gen, USAF (Ret)

Delivering on Energy Conservation

For those facilities which don’t require their chilled water system to be drained, but still have their chiller disabled for energy conservation measures from the fall into the spring, there are often energy savings left on the table. It is often discovered that when a chiller is disabled, the chilled water pump continues to operate. For instance, when an air-side economizer alone can’t meet the supply air temperature setpoint (e.g. 55°F), the chilled water control valve will begin to open. However, if the chiller has been disabled, the water will not be at a temperature suitable for cooling down the air. The valve will eventually become fully open, causing a variable speed chilled water pump to run at a higher speed but without providing any benefit. Alternatively, a constant speed pump would run at full speed, regardless of valve position.

This scenario – operating the chilled water pump without the chiller – was discovered in the 54,000-square-foot Building 643 on AFIT’s campus. An analysis of the associated energy waste was performed for the period of 1 Oct 2015 to 1 Apr 2016 through use of actual weather data (National Climatic Data Center, n.d.). Assuming the pump ran at full speed for periods with the outdoor air temperature above 55°F and at its programmed minimum speed (20 Hz) for all other times, the wasted pump energy was estimated at nearly 23,000 kWh. Considering this facility consumed 654,587 kWh of electricity in Fiscal Year 2016, halting pump operation when the chiller was disabled would have reduced the facility electrical consumption by 3.5%. This energy reduction corresponds to over $1,450 in utility bill savings (WPAFB has an energy rate of only $0.064/kWh).

Conclusion

Disabling our chillers during cooler periods of the year can create overheating issues when unexpectedly high ambient temperatures arise. The implementation of a differential dry bulb high limit control on the air-side economizer can alleviate many of the comfort complaints our HVAC shops receive in such instances. For chillers disabled in an effort to save energy, ensuring appropriate interlock between the chillers and chilled water pumps (as well as the condenser pumps and cooling tower fans if necessary) will cut out unforeseen energy waste.

References:

- Taylor, S. T., & Cheng, C. H. (2010). Economizer High Limit Controls and Why Enthalpy Economizers Don’t Work. ASHRAE Journal.

- Air Force Civil Engineer Center. (2015). Energy Management Control Systems Playbook.

- National Climatic Data Center. (n.d.). Retrieved from www.ncdc.noaa.gov

Ryan is a commissioning engineer at Questions & Solutions Engineering in Chaska, MN. As an Air Force Reservist, he serves as a mechanical systems instructor at the Air Force Institute of Technology (AFIT). Dill is the Deputy Base Civil Engineer at Portland Air National Guard Base. They are the developers of the HVAC Control Systems course taught at AFIT.